Why is Surface Roughness So Important in Manufacturing?

- David A. Davidson

- Jul 24, 2020

- 5 min read

Updated: May 29, 2021

Guest column by Mike Klein at Isofinishing Inc. For additional information or to make arrangements for free sample processing of your parts contact: Dave Davidson | Deburring/Finishing Technologist, SME Tech Community Advisor ddavidson@deburring-tech-group.com | 509.563.9859 | https://dryfinish.wixsite.com/iso-finish

Surface roughness is a component of surface texture and plays an important role in determining how an object will interact with its environment. Roughness is a good indicator of the potential performance of a mechanical component, since irregularities on the surface may form nucleation sites for cracks or corrosion. In tribology, rough surfaces usually wear more quickly and may have higher friction coefficients than smooth surfaces.

[Wikipedia Definition: Tribology is the science and engineering of interacting surfaces in relative motion. It includes the study and application of the principles of friction, lubrication and wear. Tribology is highly interdisciplinary. It draws on many academic fields, including physics, chemistry, materials science, biology and engineering. People who work in the field of tribology are referred to as tribologists.]

For some applications, some roughness may be desired to promote adhesion for cosmetic finish coatings such as painting, powder coating or plating. Surface roughness, or the texture of a surface, is a calculation of the relative roughness of a surface profile using a single numeric parameter Ra. Ra is the arithmetic average of surface heights measured across a surface. Simply average the height across the microscopic peaks and valleys. Surface roughness can be measured by a profilometer, a surface profile measurement tool. It basically reflects the average height of roughness component irregularities from a mean line. Ra provides a simple value for accept or reject decisions. (In more critical applications, with a need for more detailed 3D understanding of the overall surface texture instruments for surface texture mapping such as scanning electron micro-scopes or scanning white light optical interferometers might also be used) Maintaining surface control is critical for manufacturers and engineers to produce consistent and reliable production processes for each product. Where precision surface engineering is required, surface measurement may be a key element of maintaining control of the manufacturing, by monitoring the process to ensure it is within certain specifications.

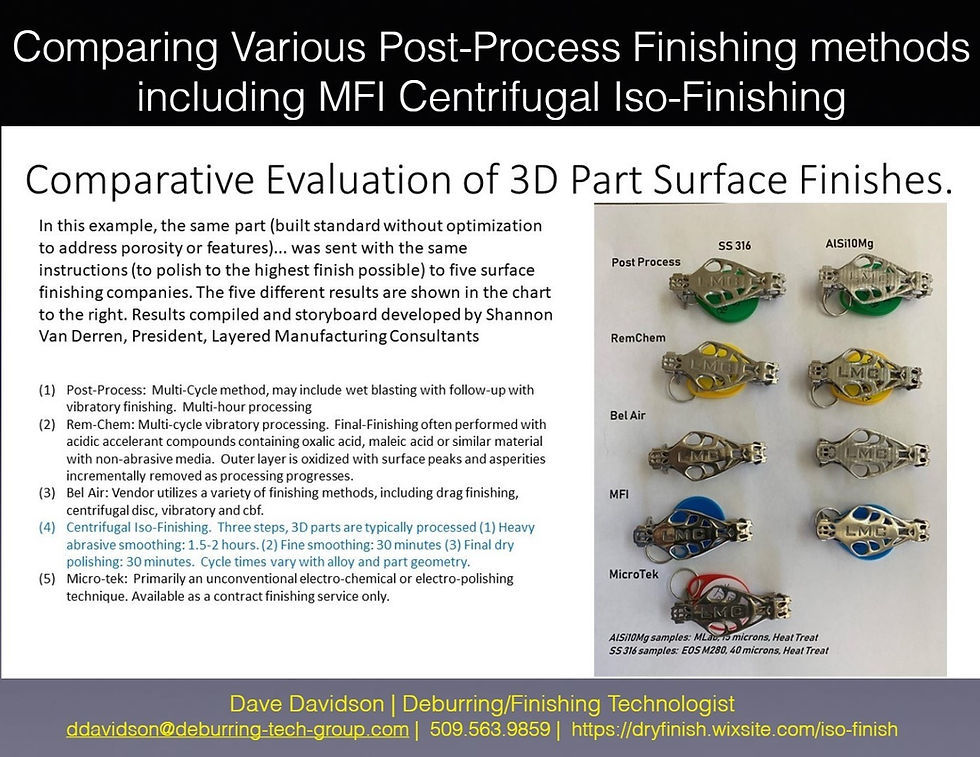

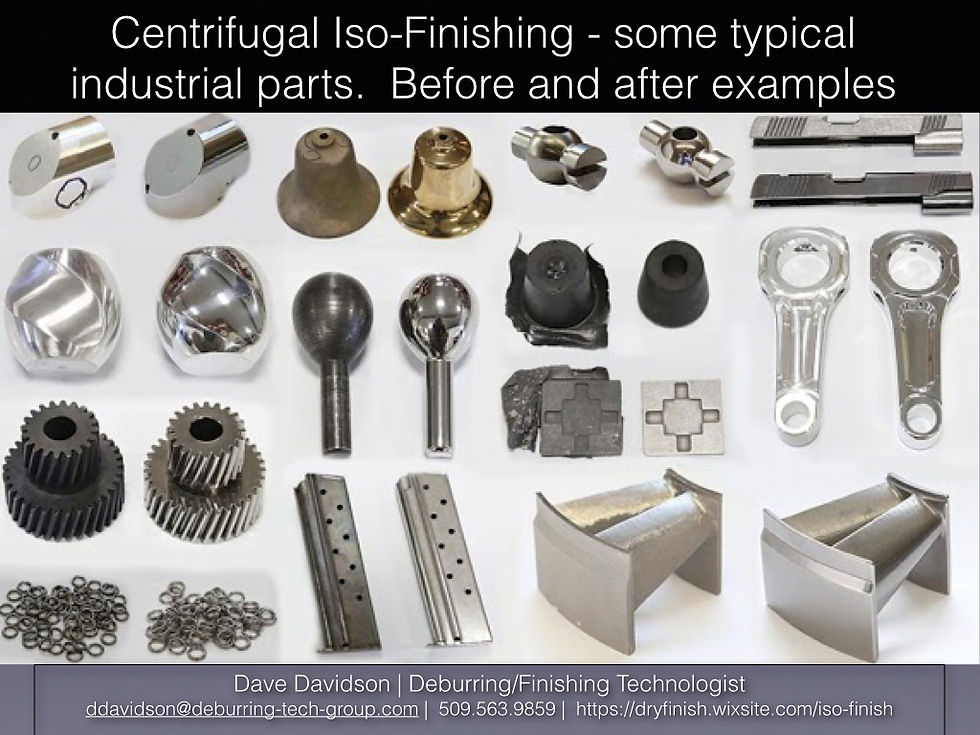

Mass finishing allows for the mechanical finishing of many parts simultaneously. Mass finishing may be used to deburr, descale, brighten, and polish parts. Mass deburring is considered a ‘loose-abrasive’ method in which batches of parts are vibrated or tumbled in specifically designed tubs or barrels along with an abrasive media. Finishing media may be produced from organic, preformed metallic, ceramic, or resin-bonded plastic materials. There are different finishing techniques used to achieve a high-quality surface finish. ISO Finishing has developed and documented processes to ensure each finished part exceeds the most demanding requirements to achieve consistent results.

Surface finish usually refers to a level of polishing or texture intended for the part or component surface. Some parts may require simple burr removal to allow them to enter the next phase of production. Other parts may require complete polishing if they are finished goods. The desired finish of a job depends on the product application, material, and type of finish your part requires.

Mass Finishing technology for deburring, finishing and polishing of machined and manufactured parts and components

Centrifugal Isotropic Finishing (CIF) is a high-energy finishing method, which has come into widespread acceptance in the last few years. Although not nearly as universal in application as vibratory finishing, a long list of important CBF applications have been developed in the last few decades.

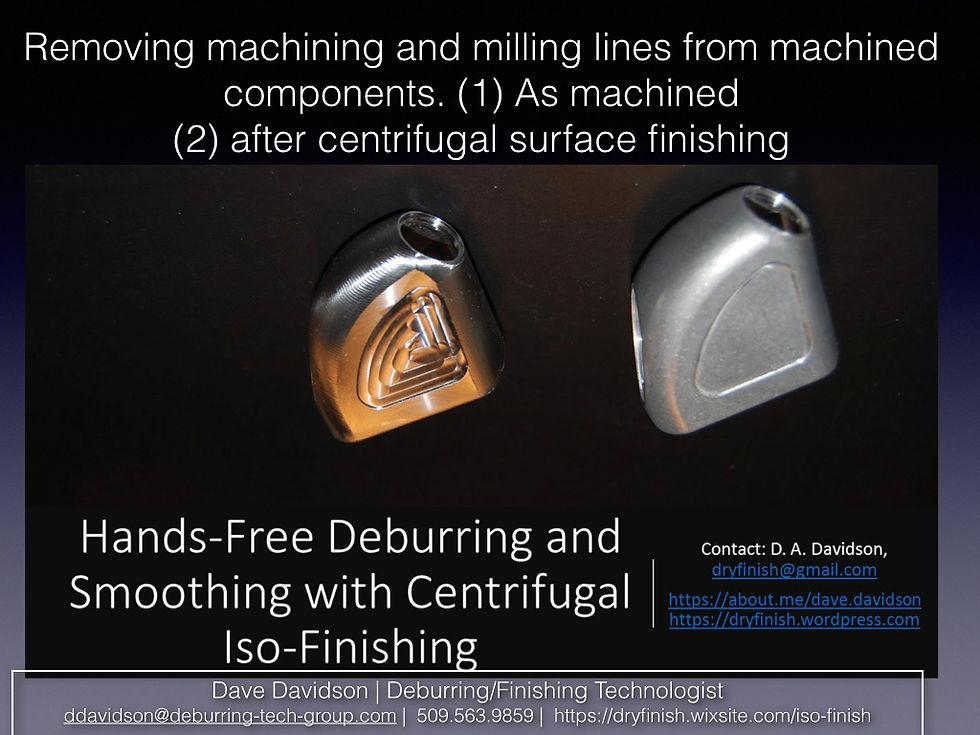

Similar in some respects to barrel finishing, in that a drum-type container is partially filled with media and set in motion to create a sliding action of the contents, CBF is different from other finishing methods in some significant ways. Among these are the high pressures developed in terms of media contact with parts, the unique sliding action induced by rotational and centrifugal forces, and accelerated abrading or finishing action. As is true with other high energy processes, because time cycles are much abbreviated, surface finishes can be developed in minutes, which might tie up conventional equipment for many hours.

Centrifugal Barrel Finishing principles – high-intensity finishing is performed with barrels mounted on the periphery of a turret. The turret rotates providing the bulk of the centrifugal action, the barrels counter-rotate to provide the sliding abrasive action on parts.

The principle behind CBF is relatively straightforward. Opposing barrels or drums are positioned circumferentially on a turret. (Most systems have either two or four barrels mounted on the turret; some manufacturers favor a vertical and others a horizontal orientation for the turret.) As the turret rotates at high speed, the barrels are counter-rotated, creating very high G-forces or pressures, as well as considerable media sliding action within the drums. Pressures as high as 50 Gs have been claimed for some equipment. The more standard equipment types range in size from 1 ft3 (30 L) to 10 ft3, although much larger equipment has been built for some applications.

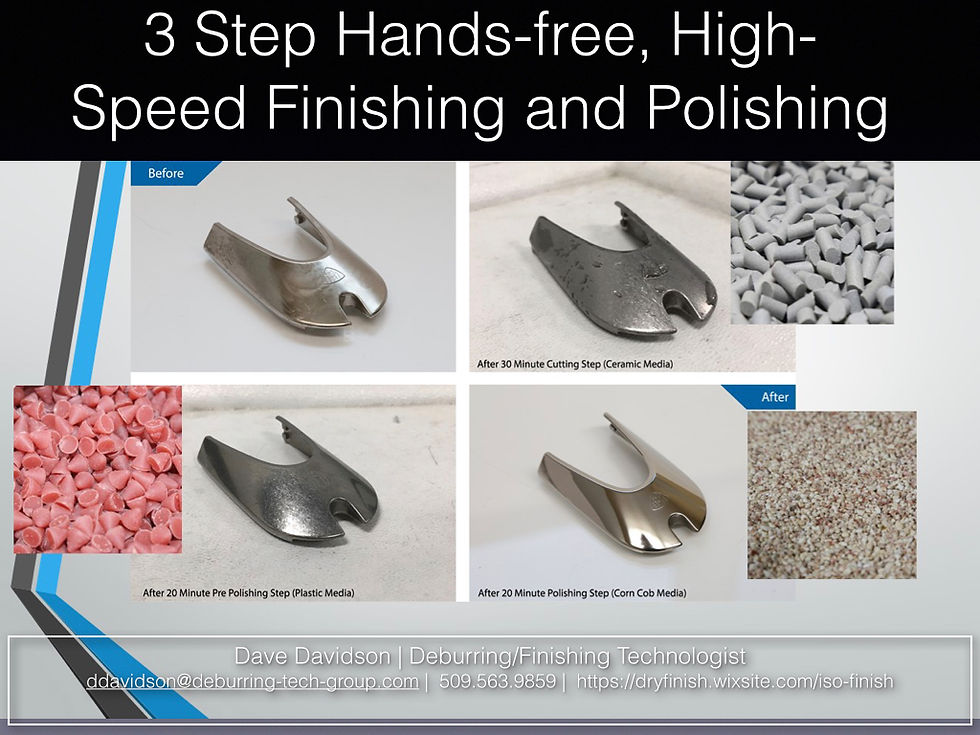

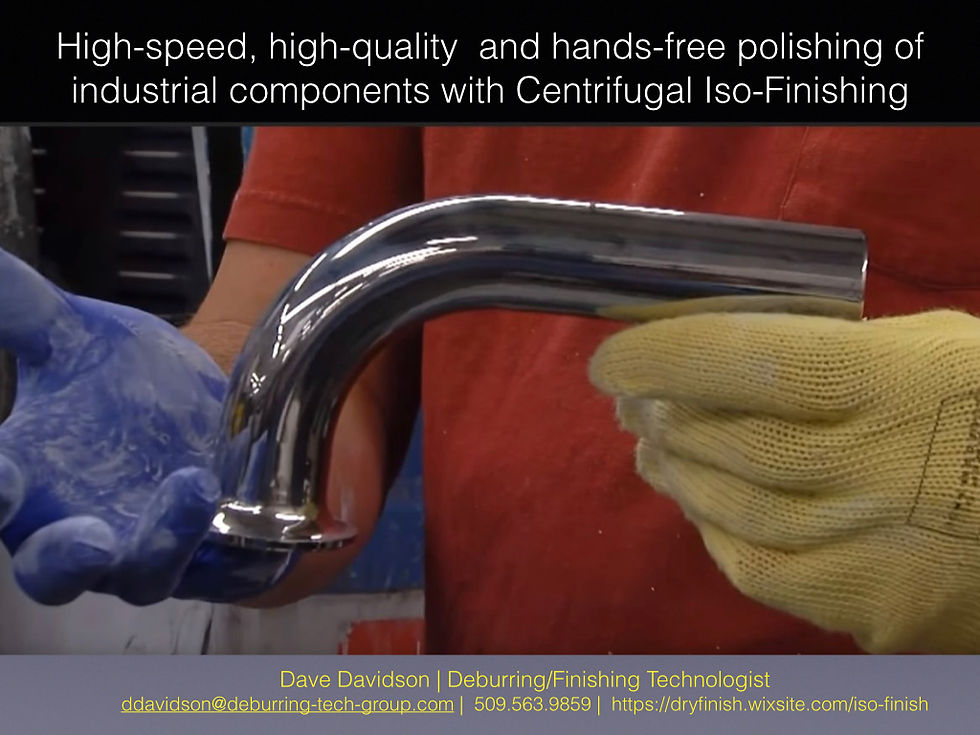

High-speed and hands-free Centrifugal Iso-Finishing can deburr, finish and polish all types of small manufactured parts much faster and efficiently than conventional vibratory and rotary barrel finishing

Media used in these types of processes tend to be a great deal smaller than the common sizes chosen for the barrel and vibratory processes. The smaller media, in such a high-pressure environment, are capable of performing much more work than would be the case in lower energy equipment. They also enhance access to all areas of the part and contribute to the ability of the equipment to develop very fine finishes. In addition to the ability to produce meaningful surface finish effects rapidly, and to produce fine finishes, CBF has the ability to impart compressive stress into critical parts that require extended metal fatigue resistance. Small and more delicate parts can also be processed with confidence, as the unique sliding action of the process seems to hold parts in position relative to each other, and there is generally little difficulty experienced with part impingement. Dry process media can be used in certain types of equipment and is useful for light deburring, polishing, and producing very refined isotropic super-finishes.

Below are some process video footage demonstrations of high-speed centrifugal isotropic finishing. These automated edge and surface finishing methods are capable of producing very refined low micro-inch surfaces that can improve functional part performance and service life.

CONTRIBUTING EDITOR BIOGRAPHY – David A. Davidson, [dryfinish@gmail.com]

Mr. Davidson is a deburring/surface finishing specialist and consultant. He has contributed technical articles to Metal Finishing and other technical and trade publications and is the author of the Mass Finishing section in the current Metal Finishing Guidebook and Directory. He has also written and lectured extensively for the Society of Manufacturing Engineers, Society of Plastics Engineers, American Electroplaters and Surface Finishers Association and the Mass Finishing Job Shops Association. Mr. Davidson’s specialty is finishing process and finishing product development.

More about Dave Davidson…

I am a deburring and surface finishing specialist, consultant and advisor to SME’s [Society of Manufacturing Engineers] Technical Community Network. The focus of my activity is assisting manufacturers and machine shops with reducing their dependence on hand or manual deburring and finishing methods, and helping them to upgrade the edge and surface finish quality of their parts. I currently work from Colville, WA but I assist clients nation-wide. I can arrange for free sample processing and process development for your challenging deburring and finishing needs and can provide you with either contract finishing services or the in-house capability to produce improved hands-free finishes on precision parts. I can be contacted at 509.563.9859 or dryfinish@gmail.com. Let me know if I can be helpful

Comments