High-Speed and Hands-Free Centrifugal Post-Processing of Additive Manufactured Parts

- Jul 15, 2019

- 2 min read

Updated: Feb 3, 2022

Guest Column by Cole Mathisen, MFI

For additional information or free sample part finishing CONTACT: Dave Davidson, Deburring/Finishing Technologist | 509.563.9859

Improve Surface Finish and achieve a High-Polish on Additive parts in minutes with Centrifugal Iso-Finishing Technology

Overview: Additive manufacturing is quickly becoming a feasible option for full-scale manufacturing. The combination of modern software, new materials and printer technology is allowing additive manufacturing or AM to bring efficiency and flexibility to manufacturing operations. The parts created using these processes are often left with very rough surfaces and scale and other imperfections. Companies using additive manufacturing need to come up with a quick solution for smoothing and polishing their parts.

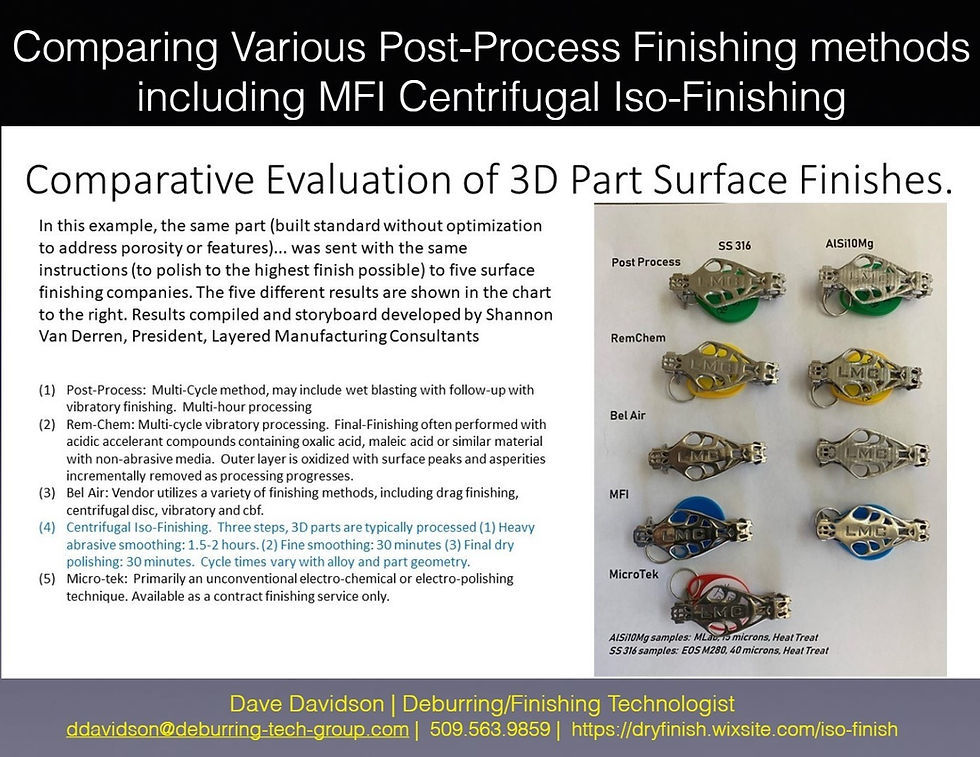

3D Printing of models is often referred to as “Rapid Prototyping.” Using traditional hand polishing methods to improve the extremely rough surfaces of these parts is anything but “Rapid.” An operator can spend days to get all of the surfaces smoothed out by hand. Centrifugal Iso-Finishing processes can achieve a polish on several parts at once (Like the ones featured above) in just two hours.

The Process: Achieving a polish on a 3D Printed part depends greatly on the material and the initial roughness and scale left over from the printing process. On relatively clean (no heavy heat scale or atmospheric discoloration) titanium or stainless steel 3D printed parts with an initial surface roughness of 300-400 micro-inch Ra here is a typical example process that is used with Centrifugal Iso-Finishing Machines:

Step One: Heavy grinding with aggressive plastic or ceramic media for 60 Minutes

Step Two: Pre-Polish with lighter plastic for 30 Minutes

Step Three: High Polish with dry corn cob polishing media or porcelain for 30 Minutes

Total process time Two Hours (Not including loading)

Equipment Recommendation: 3D printed parts that have a high production volume to justify tumbling equipment tend to be smaller in size. For this reason the HZ-40 is a popular option. Its small footprint (roughly 3′ x 4′) makes it ideal for fitting into tight lab operations. See a video of an HZ-40 machine in operation below:

For parts that are too large to fit in the HZ-40 barrel (longer than 10 inches and wider than 5 inches) a larger machine like the HZ-60, HZ-120 or HZ-160 with a bigger processing chamber is required. See a smoothing and polishing operation being performed in an HZ-60 Centrifugal machine below:

Above: various 3D printed parts surface finished, burnished or polished

If you have additive parts and are looking for smooth surfaces or highly polished parts, contact Dave Davidson at ddavidson@deburring-tech-group.com for free sample part finishing information

BELOW: Many machined, cast and fabricated parts are also finished and polished with the Centrifugal Iso-Finishing method.

ABOVE: Many conventional (subtractive) parts2 can also be processed with high-speed and hands-free Centrifugal Iso-Finishing processes

For additional information, technical assistance and free sample part finishing contact Dave Davidson at ddavidson@deburring-tech-group.com or +1.509.563.9859 (WhatsApp)

Comments