CASE STUDY: Centrifugal Iso-Finishing Technology and 3D printed (additive manufactured) parts.

- Jun 23, 2020

- 2 min read

Updated: May 29, 2021

For additional technical information and help with sample part processing your parts CONTACT: Dave Davidson | Deburring/Surface Finishing Technologist

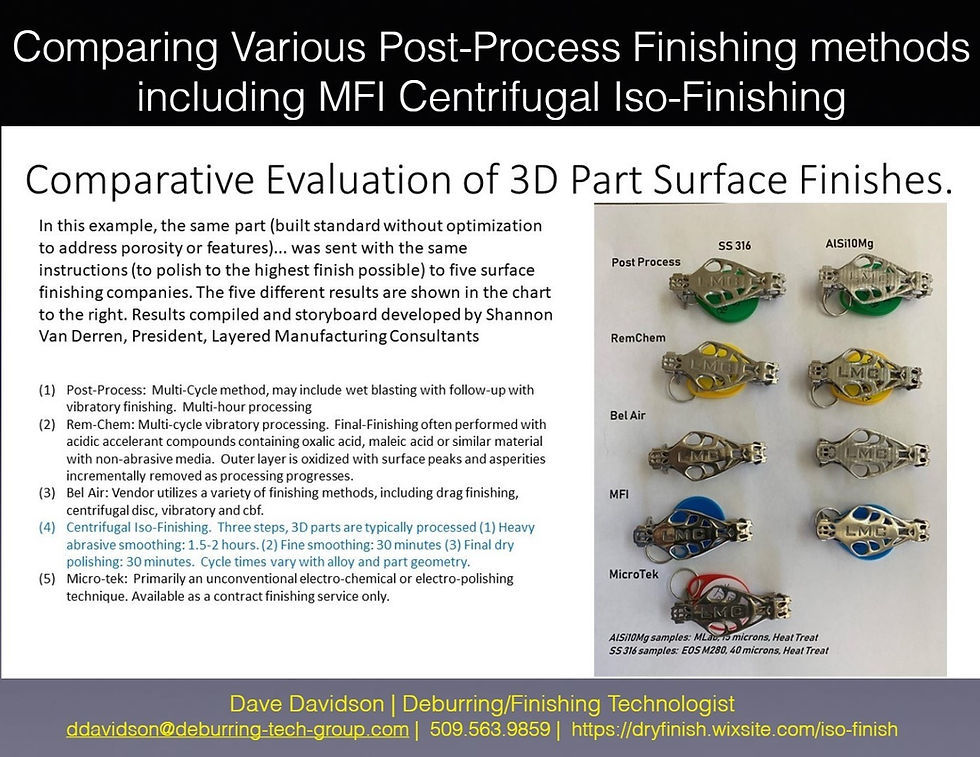

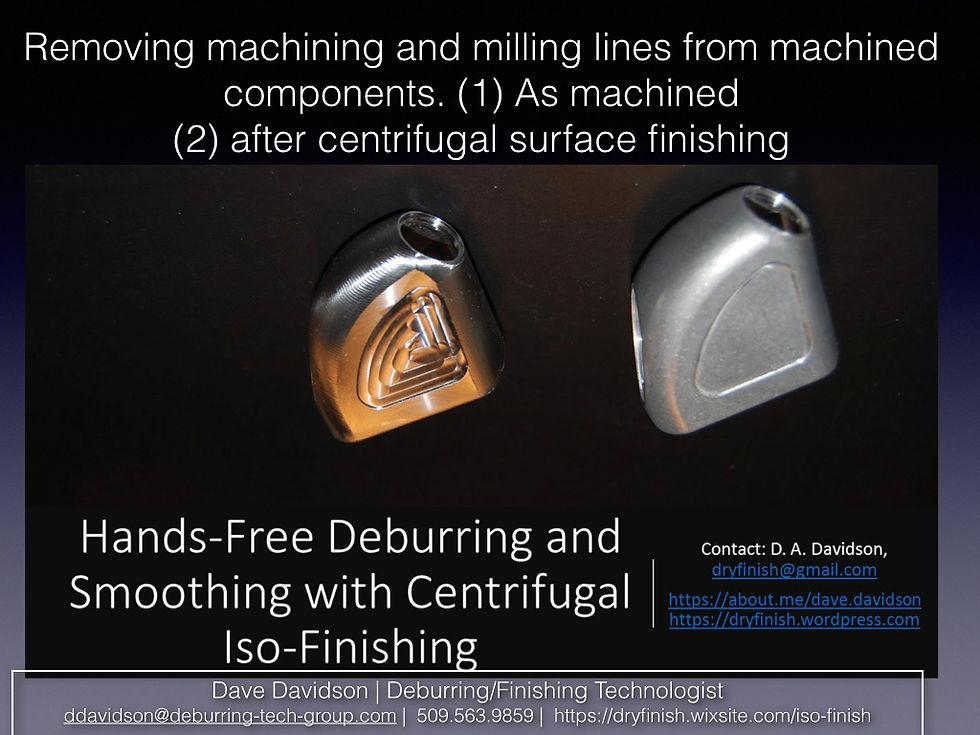

3D LOGIC’S CHALLENGE: Established in early 2018, 3D Logics was adept at creating parts that were accurate and consistent, but often had inherent surface roughness. The company had persistent finishing challenges with metal products, particularly titanium and nickel-based Inconel parts which are extremely tough and require high energy and very exact media to properly finish. Being a startup with just a few employees, 3D Logics wanted a partner that could provide finishing expertise and advice, as well as a selection of specialized media that would enable them to provide high end finished parts to their growing customer base.

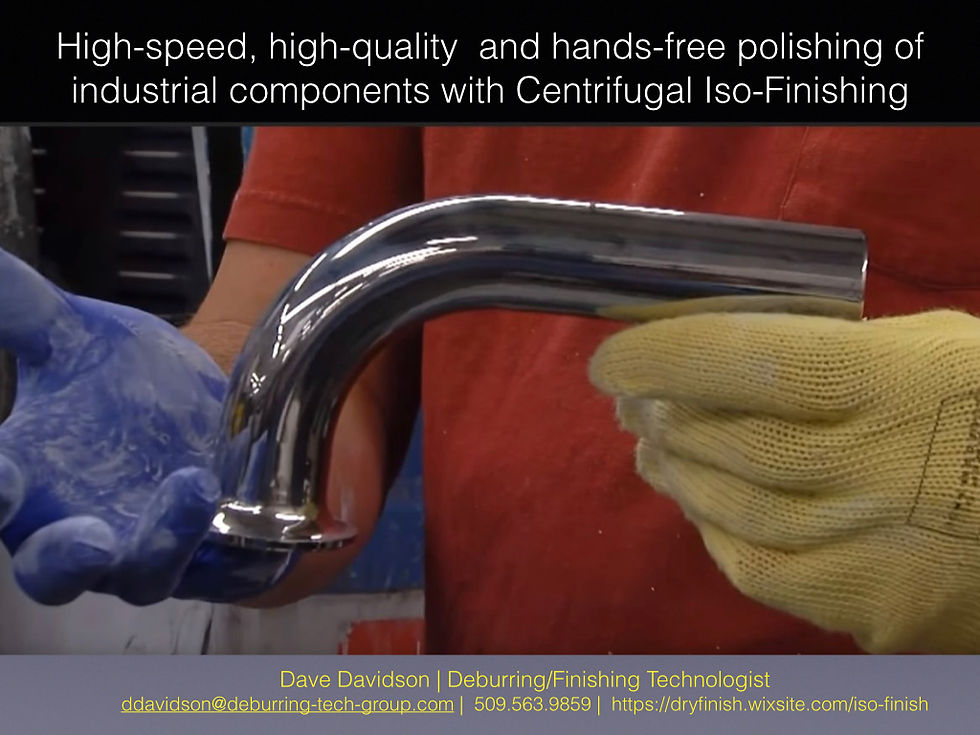

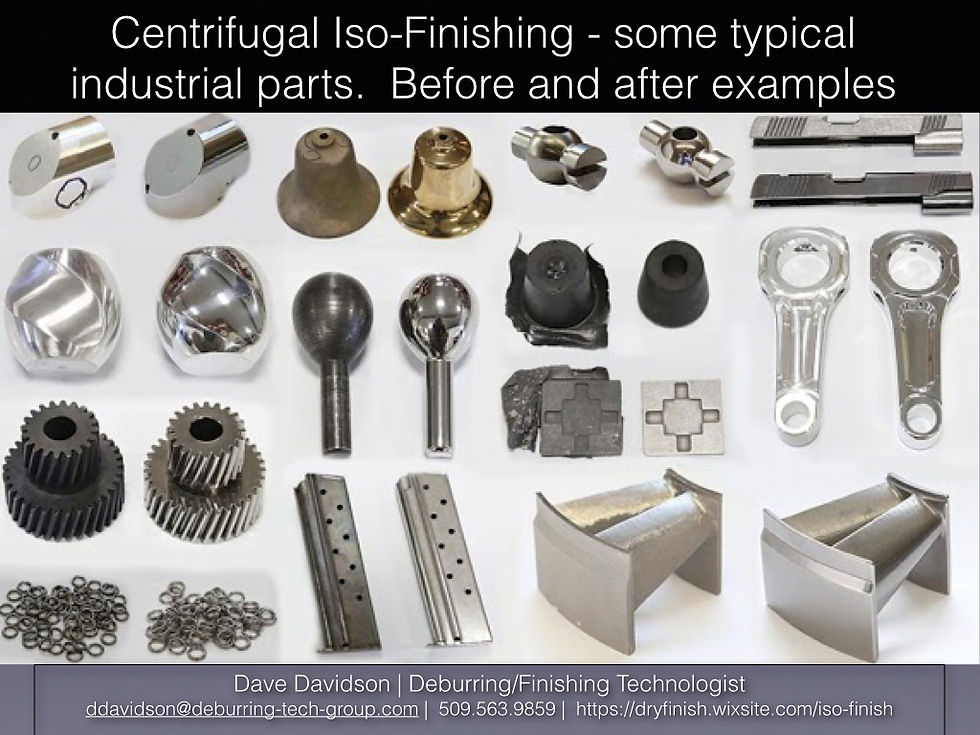

THE SOLUTION: Centrifugal Iso-Finishing. 3D Logics evaluated many different types of finishing equipment, but ultimately settled on Centrifugal Iso-Finishing machines made by MFI. MFI had the whole package they were looking for – the best systems (made in Minnesota), years of experience and a large selection of media. 3D Logics purchased an HZ-40 High Energy Centrifugal Iso-Finishing (CBF) Machine, and MFI partnered with them to help their employees gain a better understanding of which media to use depending on the material, size and shape of the item. Whenever 3D Logics has a new part, they can send it the MFI technical team, who will develop the finishing process and send a report so 3D Logics can provide their customers with the highest quality metal and plastic/polymer parts.

THE RESULTS: Thanks to their HZ-40 CBF and technical assistance from MFI, now 3D Logics can put a mirror finish on their titanium parts, and get precisely finished parts in 20 to 30 minutes. 3D Logics Owner Sterling Logan is very pleased with his HZ-40 CBF and happy to recommend MFI to anyone who has finishing questions. He appreciates the MFI technical team’s help, quick response, and honesty to tell him when a barrel finisher isn’t the best finishing solution. That’s because they don’t just want to sell him a machine and media, they want him to have the best possible solution.

“Our customers immediately noticed a difference when we started using the Centrifugal Iso-Finishing machine. They asked, ‘Wow, are these 3D parts? This is incredible, these parts are amazing. What did you do?’ MFI gives us a leg up on the competition and we’re happy to partner with them. Anyone seriously looking at barrel finishers should take a close look at MFI. They would be in good hands.”

3D Logics Owner: Sterling Logan

3D Logics is now an ISO 9001:2015 & ISO 13485:2016 certified manufacturing facility.

For information about 3D Logics, visit their website at https://3dlogics.com/

Or reach out directly:

Address: 5293 NE Elam Young Parkway, Suite 150, Hillsboro, OR 97124 Email: info@3dlogics.com Telephone: (503) 455-8450

See below: other 3D printed part finishing applications

For additional technical information or for a free sample part finishing trial contact Dave Davidson

at ddavidson@deburring-tech-group.com or my mobile at +1.509.563.9859

Comments