CENTRIFUGAL ISO-FINISHING TECHNOLOGY: A Keynote Summary Presentation Slide Deck.

- May 16, 2021

- 2 min read

Updated: Feb 17, 2022

For additional information contact: Dave Davidson | Deburring/Surface Finishing Technologist

Email: ddavidson@deburring-tech-group.com | See also the technical blog at: dryfinish.wordpress.com

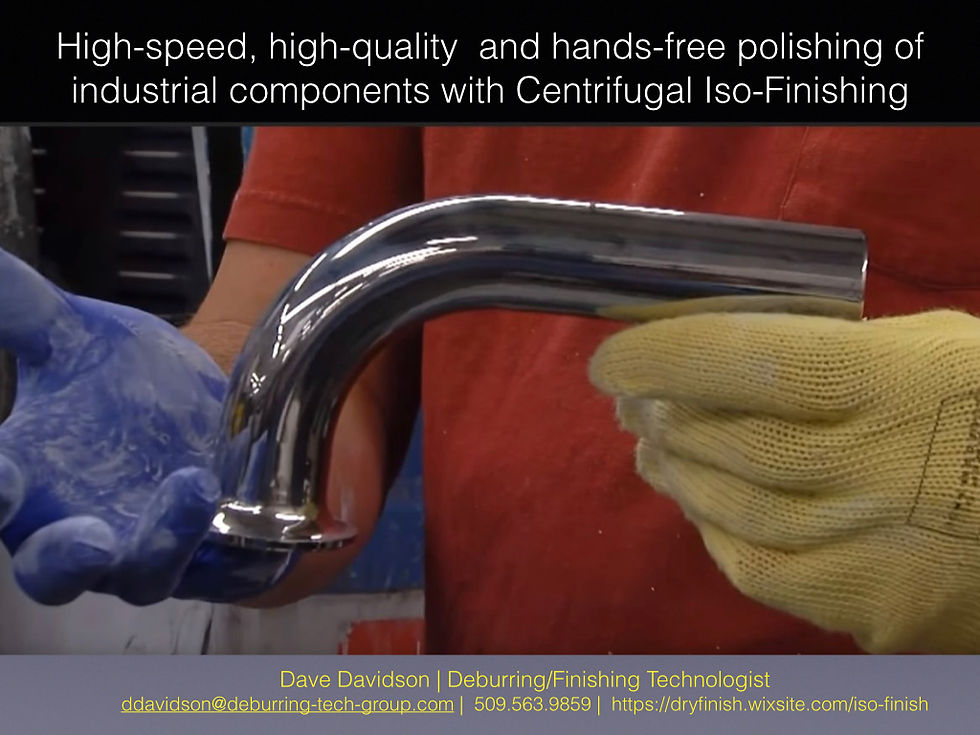

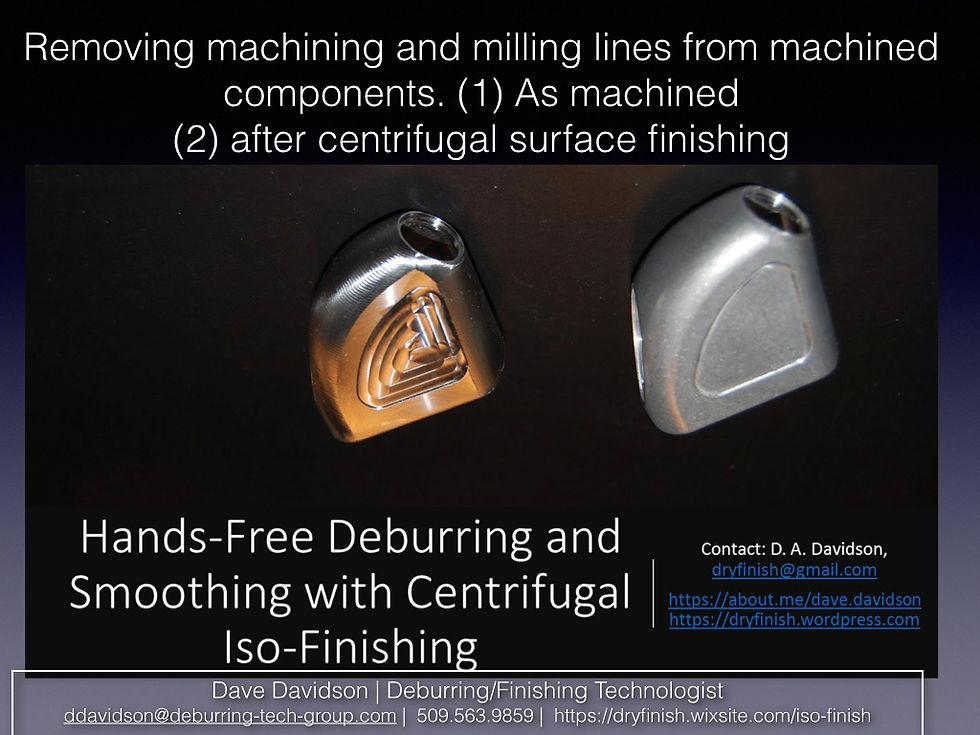

The slide presentation below provides an executive summary or overview of the Centrifugal Iso-Finishing Technology. This high-speed, high-quality and hands-free method is used throughout the manufacturing industry for part deburring, surface finishing and polishing.

See below the various types and sizes of various Centrifugal Iso-Finishing Machine models.

See below video posts that show parts that have been finished and/or polished with Centrifugal iso-Finishing as well video posts showing the equipment in action.

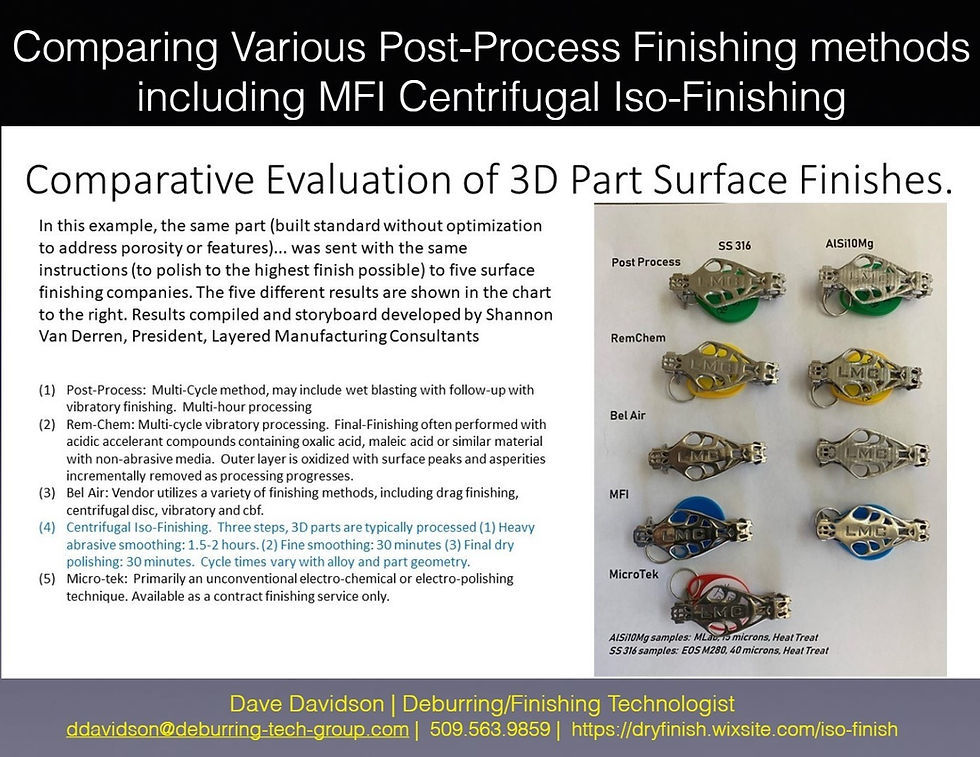

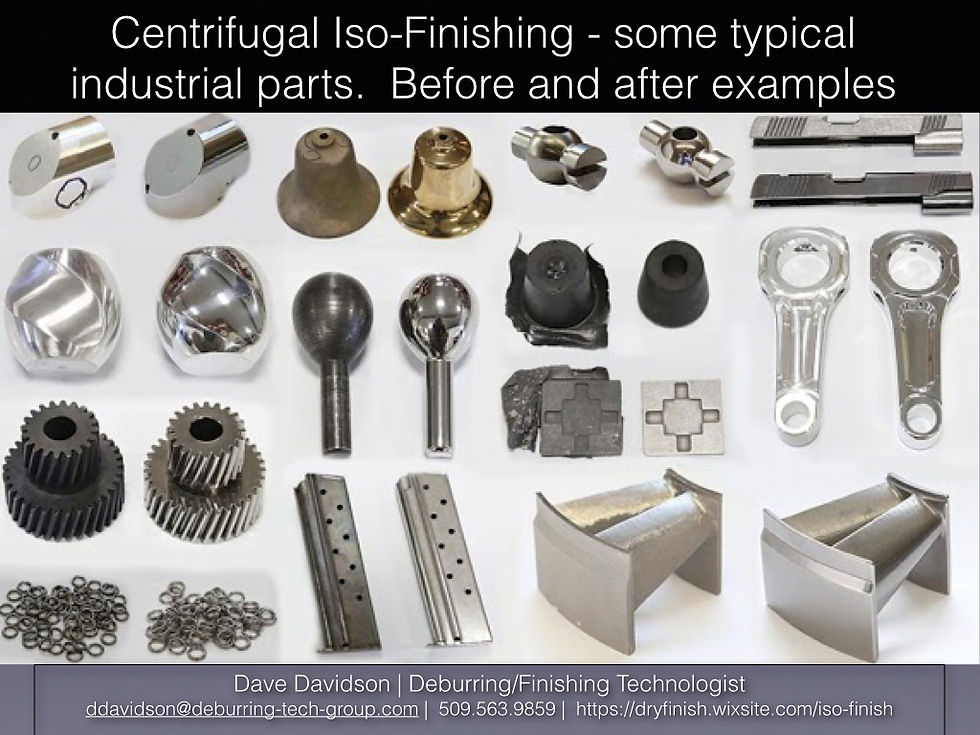

Before and after parts showing surface finishing of the Centrifugal Iso-Finishing process, includes examples of additive manufactured parts.

The video compares hand-deburring and hand-polishing with Centrifugal Iso-Finishing Techniques.

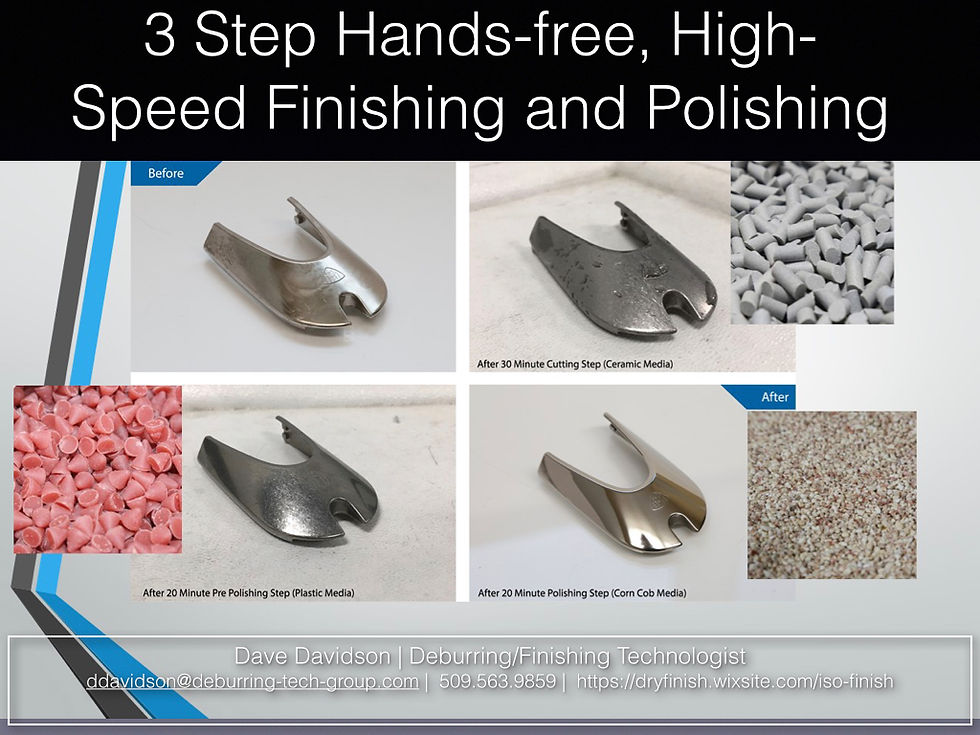

The video gives an example of a three-step machine process that can produce highly polished parts without manual intervention

This video gives a rundown about larger Centrifugal Iso-Finishing equipment capable of processing larger dimensioned parts or larger batches

Used widely for small parts processing I the jewelry, medical, dental and additive manufacturing industries this machine is ideal for finishing situations that involve small to moderate volumes of small metal and plastic parts.

This video is of a larger Centrifugal Iso-Finishing machine processing machined parts at a large machine shop. Over 50 different part numbers are processed with the machine from various alloys ranging from aluminum to stainless steel and up through titanium parts. Operations run from deburring, to surface smoothing with machining line removal and highly polishing parts that require decorative surfaces.

Contact us for technical assistance or free sample part processing of your parts...

For additional information contact: Dave Davidson | Deburring/Surface Finishing Technologist

Email: ddavidson@deburring-tech-group.com | See also the technical blog at: dryfinish.wordpress.com

Comments