Sample Part Processing Information and the Deburring/Finishing Technical Group

- May 6, 2019

- 3 min read

Updated: Jan 24, 2022

Need more information? Contact: Dave Davidson | ddavidson@deburring-tech-group.co

Contract Finishing and Polishing. We have worked with manufacturers in industries ranging from medical and aerospace to firearms and OEMs to carry out finishing services and create finished products. These unique industries and their products require attention to the finest of details—and yield virtually no room for error. Our process includes several steps to ensure parts and product reliability:

Custom Development Strategy. There is no magic here—it’s precision. We customize each finishing process to fit our clients’ needs from start to finish. At the end of the day, we specialize in you. Our centrifugal barrel finishing services are custom-tailored for each specific component.

Samples & Quality. We formulate a process for each product and provide our clients with finished samples at no charge. Collaboration with the customer is key. If something needs improvement, we’ll use the client feedback to adjust the process. The result is a customized, consistent, and repeatable set of specifications for finishing your unique product.

We are also Isotropic Finishing Specialists for All Major Industries. We serve many different manufacturing clients nationwide. For superior surface finishing and finishing equipment sales, choose ISO Finishing. Small businesses to large Fortune 500 customers choose our mass finishing services based on our 75 years of experience of providing innovative, quality solutions and our superior customer service.

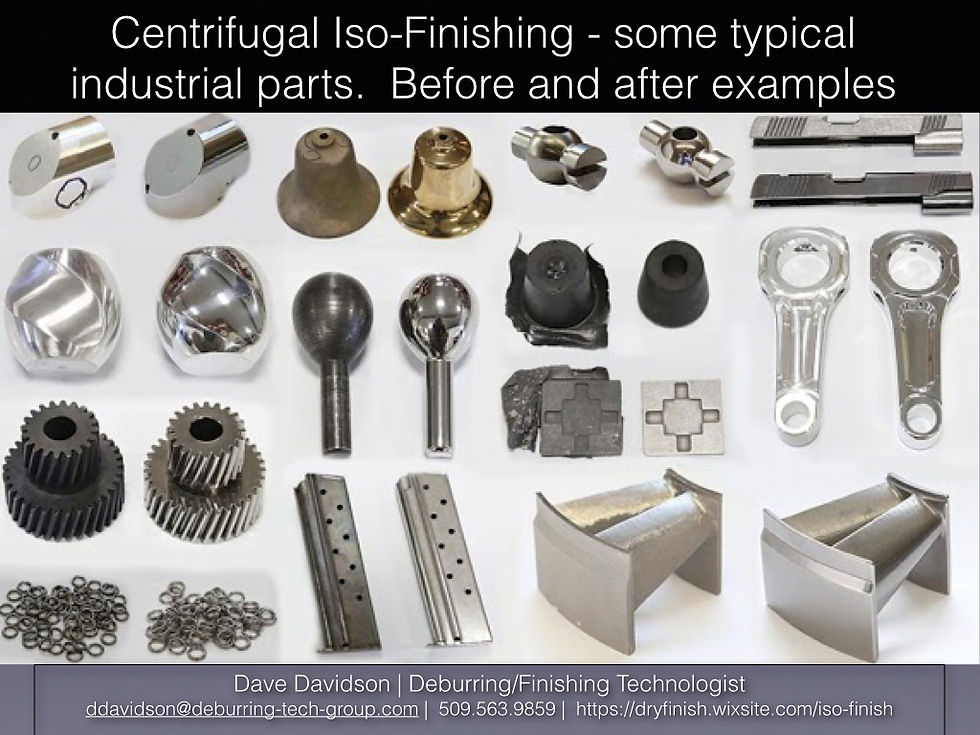

ABOVE:: Some before and after examples of part finishing with the Centrifugal iso-Finishing method.

As an isotropic finishing service provider, ISO Finishing specializes in vibratory finishing, high energy polishing and micro-precision surface improvement. We are known for our quality metal finishing expertise on titanium, aluminum, stainless steel, carbon steel, brass, and copper. Our ability to finish plastic, rubber, silicone and ceramic parts along with our custom metal finishing work, allows our services to extend to an array of industries, including Injection Molding, OEM’s, Firearms, Medical, Automotive, Dental and Aerospace.

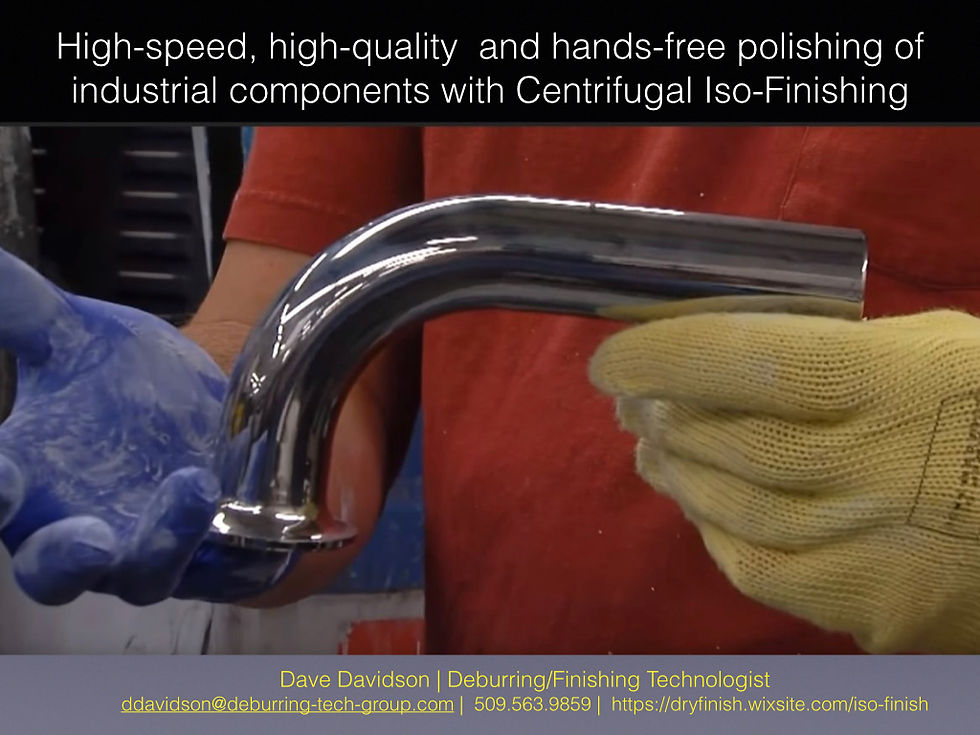

ABOVE: A demonstration of the Centrifugal Iso-Finishing process where parts are smoothed and polished in short centrifugal finishing cycles. Many different types of parts are finished with this method, different alloys can be processed by utilizing different abrasive and polishing media formulations.

To make arrangements for sample part processing of your parts with the Centrifugal Iso-Finishing method: Contact Dave Davidson, Senior Technical Advisor at Deburring/Finishing Technical Group at ddavidson@deburring-tech-group.com or 509.563.9859 The procedure is simple:

(1) Fill out the Sample Part Intake Form to document your parts and the finish desired.

(2) Snap some smartphone pictures. Send the form and pictures to my email shown above prior to shipping the parts so I can make an initial assessment.

(3) Package the parts and label the package for shipment to Loretto, MN

(4) Include the parts along with a paper copy of the Sample Part Finishing Form and ship.

Here is a link to the: ISO-FINISHING REQUEST FOR SAMPLE FINISHING – CONFIDENTIAL WORKSHEET (WORD document) to complete on your computer

SEE: https://drive.google.com/open?id=1wPg-CeP4KWHjreLBsSjb1JsR2KC2zG0oOaISqmxShaU If you have trouble with the link, email me and ask for the form to be sent to you as an attachment.

The SHIP TO address is shown below. Send your ample part shipment, along with a hard copy of this form to: ISO-FINISHING (Process Engineering) Attn: M. Klein and D. A. Davidson 50 South Medina Street Loretto, MN 55357 USA

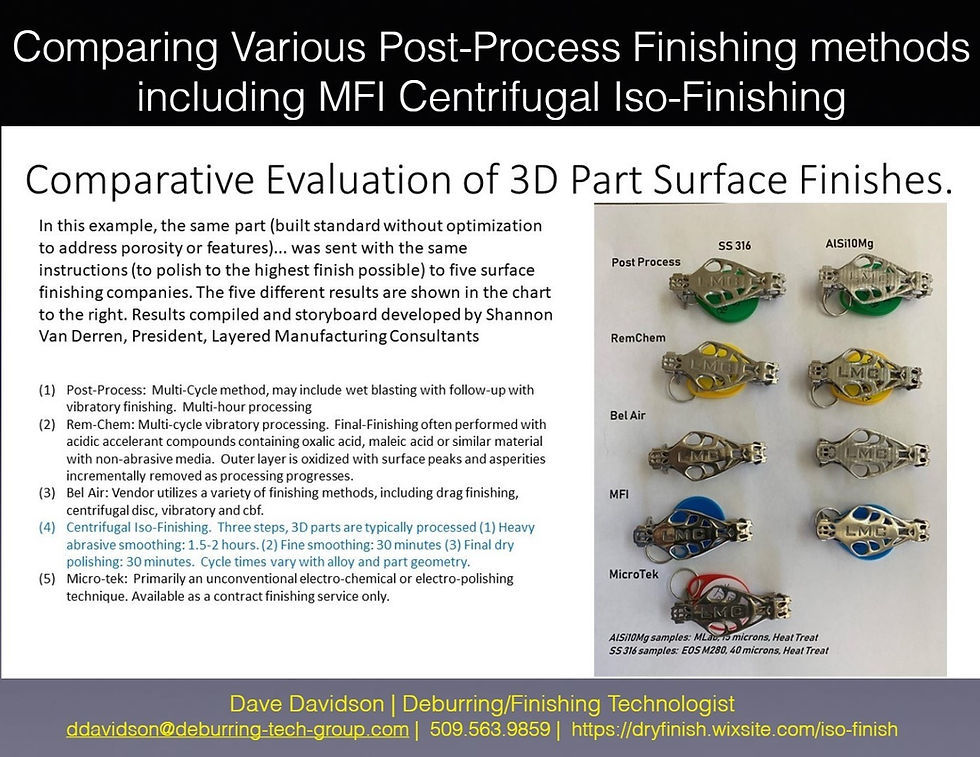

Some examples of the work and processes performed can be seen in the information shown below:

ABOVE: Some examples of the types of deburring and surface finish work performed at Isofinishing, Inc.

BELOW: Video Tour of the ISO-Finishing Contract Finishing Service Bureau and Process Development Test Center.

ISO-FINISHING REQUEST FOR SAMPLE FINISHING – CONFIDENTIAL WORKSHEET

(Please include a paper hard copy of this sheet with your sample part shipment)

Instructions: Please complete the form below. Email the form to Dave Davidson at: ddavidson@deburring-tech-group.com This form is also available as a WORD document, email me at this address and I will send you a copy as an attachment

Send Sample part shipment, along with a hard copy of this form to: ISO-FINISHING (Process Engineering) Attn: M. Klein and D. A. Davidson 50 South Medina Street Loretto, MN 55357 USA

DATE:

COMPANY:

Contact Person

Email Address:

Telephone:

Delivery Address:

City:

State/Province

Postal Code:

Country:

PART INFORMATION: Part Name and Description: Part Material: Part dimensions: L” x W” x D’ or Length x Diameter

PRODUCTION or PROJECTED PRODUCTION QUANTITIES

Parts per shift?: Parts per month or year?:

THIS SAMPLE PART FINISHING SHIPMENT:

Number of Sample Parts included with this shipment?

Expedited shipping to return parts? Y/N

Expedited Shipping via:

Your company account No.

OTHER PART INFORMATION

Manufacturing operation(s) prior to finishing: Post-finishing operations: Description of Part Finishing Needs or Requirements: Radius or Surface Finish requirement or specification:

Additional Notes or Comments

PLEASE ATTACH PHOTO OF PARTS IF POSSIBLE (Smart-phone Photos are OK) and send to my Email at ddavidson@deburring-tech-group.com

David A. Davidson Deburring/Finishing Technologist 33 Beeler Road, Crawfordville, FL 32327 USA Mobile: +1 (509) 563-9859 (International Calls with Whats App-Toll Free) Email: ddavidson@deburring-tech-group.com Website: https://dryfinish.wordpress.com

Comments