Surface Polishing of Orthopedic parts with high-speed and high-quality Centrifugal Iso-Finishing

- Apr 30, 2021

- 2 min read

Updated: May 29, 2021

Guest column by Mike Klein, CTO, Iso-Finishing Inc. For additional information contact Dave Davidson | Deburring/Surface Finishing Technologist ddavidson@deburring-tech-group.com | https://dryfinish.wordpress.com

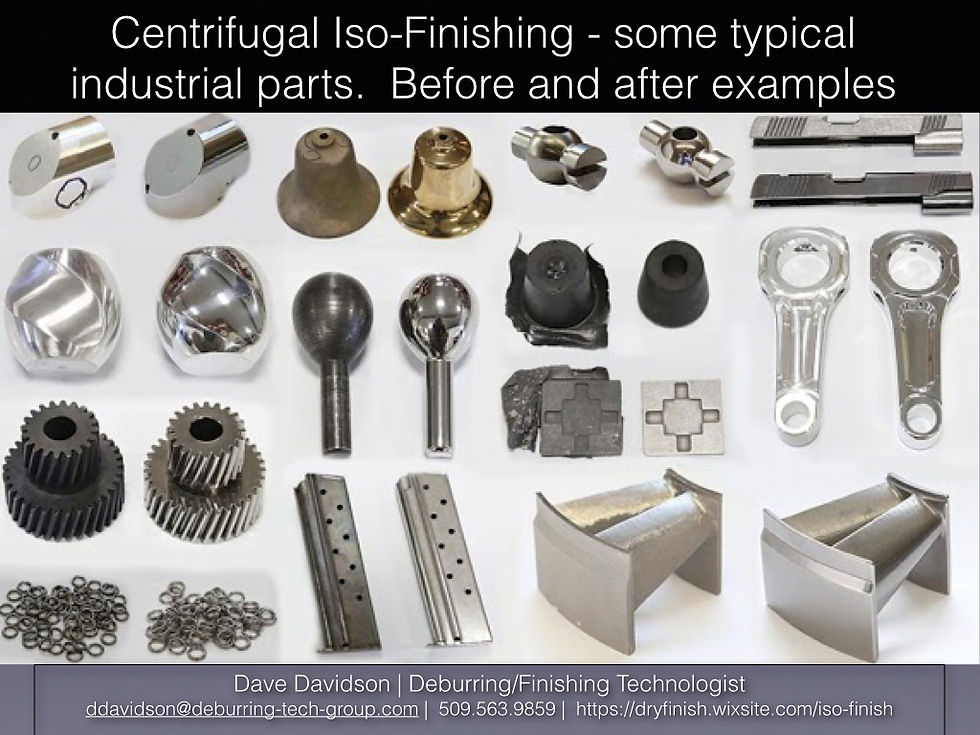

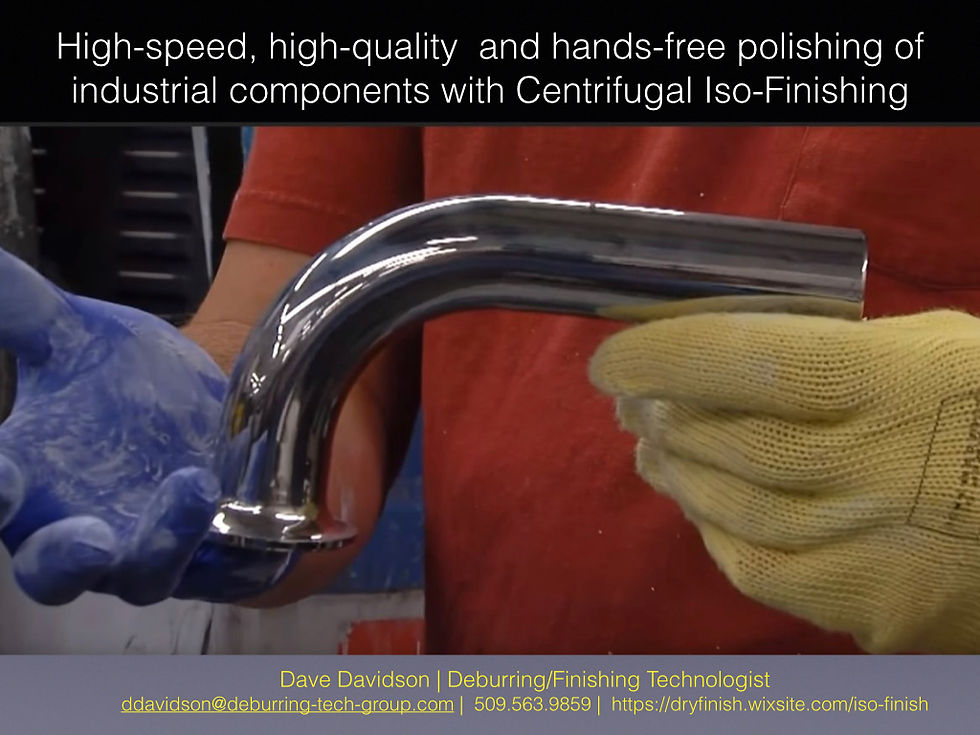

Surface polishing plays a vital role in the performance of parts in a variety of industries, especially when it comes to orthopedic part polishing. From aviation and aerospace to performance motorsports, surface polishing influences how well parts perform. While critical for many industries, the performance of polished parts is perhaps most integral in the medical industry. Surface finishing of orthopedic parts such as artificial joints is crucial to a patient’s recovery and quality of life. With patient outcomes in mind, consistently achieving production efficiency, dimensional accuracy, and high-performance surfaces is essential to orthopedic component manufacturing. Mass finishing provides the perfect solution for creating superior surface functionality. Surface finishing processes like vibratory and centrifugal barrel finishing quickly and reliably delivering the results required for orthopedic parts such as:

Bone Plates

Suture Anchors

Reattachment Buttons

Surgical Tools

Artificial Joints

Benefits of Surface Polishing for Orthopedic Parts. In addition to achieving the ultra-smooth surfaces demanded by the industry, surface polishing has several benefits for orthopedic parts.

Improved Strength and Lifespan Parts having undergone surface polishing are stronger, more durable, and longer-lasting than unfinished parts. Polished orthopedic parts also have a stronger resistance to corrosion, which is imperative when dealing with components implanted in the body. Polishing helps improve surgical success and patients’ quality of life.

Polishing Prevents Part Fatigue Ensuring orthopedic parts are long-lasting requires special attention to part fatigue, a phenomenon occurring when a part or structural component experiences cracking and subsequent failure due to alternating or cyclical stressors. Part fatigue can have dire consequences for patients with medical devices and implants such as artificial joints and bone stems. The polishing process eliminates stressors that cause part fatigue, creating a uniform finish free of abrupt surface changes. It also helps to prepare metal orthopedic parts for any surface coatings they may receive.

Cleaner, More Sanitary Tools and Components Hygiene is an important aspect of every facet of patient care, whether it’s the environment where they are treated or the tools and components used. The quality of those tools and components can have a direct impact on patient outcomes. Orthopedic components and surgical instruments with a smoother surface prevent contaminants like bacteria from clinging to the part’s exterior. The parts are also much easier to clean and sanitize, effectively improving patient safety and recovery.

ISO Finishing is an Industry Leader in Surface Finishing for Orthopedic Components. Over the years, ISO Finishing has worked with a wide range of materials, including stainless steel, cobalt chrome, titanium, and polymer alloys. Our experience has enabled us to develop proven processes that meet or exceed strict medical requirements. We provide a range of polishing methods for orthopedic parts and instruments, including vibratory and centrifugal barrel polishing. In addition to polishing, ISO Finishing offers the following services for the medical industry:

Deflashing

Anodizing

Radiusing

Ultrasonic Cleaning

If you’d like to learn more about ISO Finishing’s services or request a free sample finishing trial, please contact our team. For additional information and help with arranging for a free sample finishing trial for your parts contact: Dave Davidson at ddavidson@deburring-tech-group.com

Comments