F A Q: Centrifugal Iso-Finishing Processes and Applications

- Jun 7, 2022

- 4 min read

Updated: Jun 8, 2022

CONTACT INFORMATION: Dave Davidson | Mobile: +1.509.563.9859 (WhatsApp - International) (Work email) ddavidson@deburring-tech-group.com * Web-page https://dryfinish.wixsite.com/iso-finish

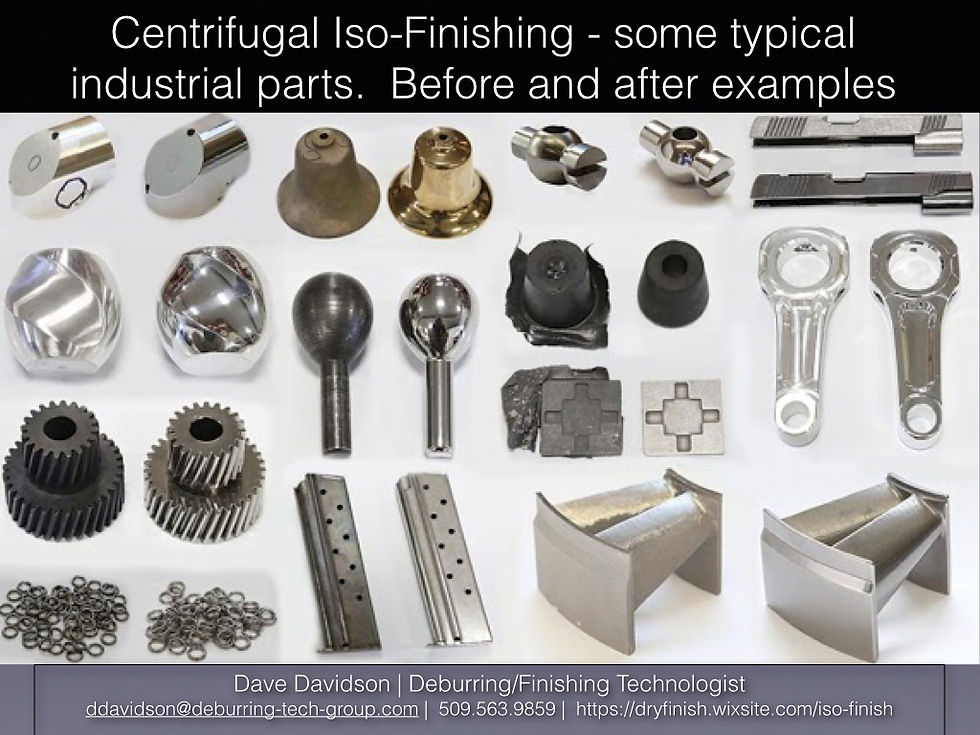

Thank you for making a connection with us. I thought I would follow up by bringing you up to date on our current procedures for sending us parts for sample finishing and process development. Additionally, in this newsletter, we will mention some recent Centrifugal Iso-Finishing Applications and a run-down of pointers to help you optimize your processing. We will do this in a FAQ format. First, here is a photo gallery of some parts that have been processed with centrifugal iso-finishing: SEE: https://dryfinish.wixsite.com/iso-finish

Some Frequently Asked Questions:

How do I get a quotation on having my parts contract finished or post-processed with centrifugal iso-finishing? First, send me your contact information and some smart-phone photos of the part(s) so I can make an initial assessment. Send this information to my ddavidson@deburring-tech-group.com email address. If the assessment shows that the parts are good candidates for centrifugal iso-finishing then use this form to give us part information that will help the process engineers with their process development effort. The form is in a WORD document format and can be filled out on your computer. Use this link to access the form and download it: https://drive.google.com/open?id=1wPg-CeP4KWHjreLB...

(NOTE: If the link gives you trouble, let me know and I will send the document as an e-mail attachment) For more information on these job shop operations see this tech blog article. which also includes a video of operations in the shop: https://bit.ly/3NddftV

ABOVE: Centrifugal Iso-Finishing operations at the IsoFinishing company, a large contract finishing job shop located close to Minneapolis, MN

What if we want to do the centrifugal iso-finishing process at our facility? We can also help you with your equipment needs. Send sample parts using the directions on the form at this this link: https://docs.google.com/document/d/1SkWoi4-tdufndtLrdp1TTm9O-SzQvy99/edit?usp=sharing&ouid=102024248875162955824&rtpof=true&sd=true We will return the parts to you for evaluation and provide you with a budgetary quotation on the equipment that is the most appropriate for your application. Here (shown below) is an example of some parts being finished and polished in the sample part processing laboratory: https://www.youtube.com/watch?v=POvQYi5CqJQ

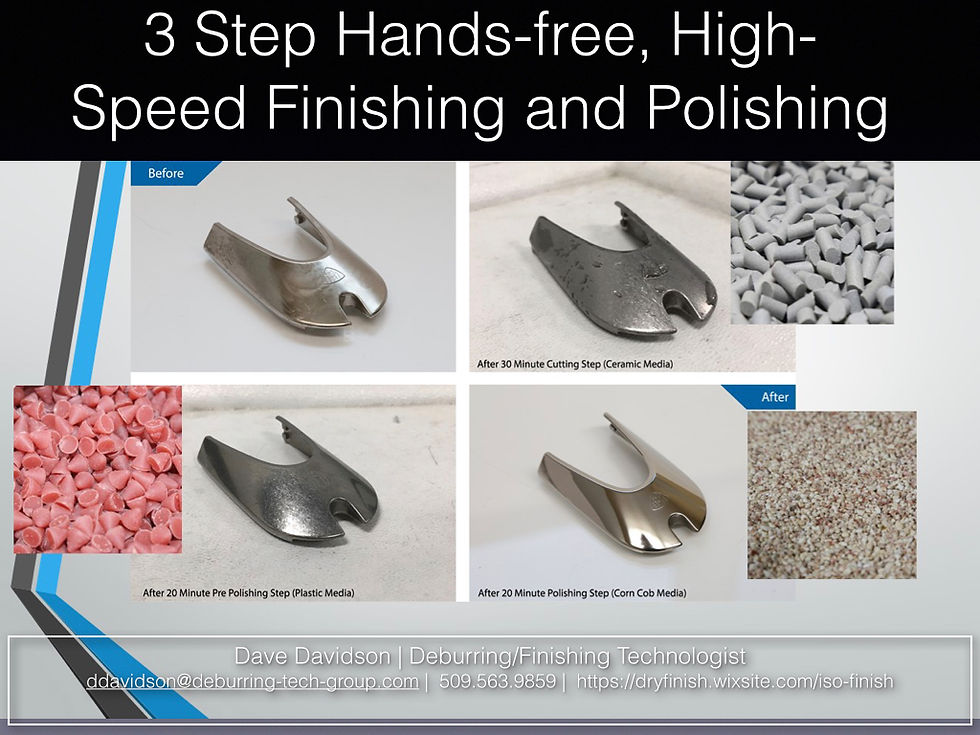

ABOVE: This video demonstrates a three step Centrifugal Iso-Finishing process used for deburring, smoothing and polishing of parts in a Model HZ-60 Centrifugal Barrel Finishing machine. The video also shows the use of barrel dividers used to keep parts separate in order to prevent part-on-part contact. Smaller parts can also be run in bulk with the process.

I have parts that need to be kept separate from each other while processing, what can you do for me? With Centrifugal Iso-Finishing processes, this is a problem that is easily solved. The equipment's processing compartments have slots to which divider inserts can be inserted in order to subdivide the processing compartment into smaller pockets. In this way, parts can be processed individually with no concerns about part-on-part contact. See how this is done in our technical blog post on the subject: https://bit.ly/3Nsjrh6

Can Centrifugal Iso-Finishing be used for finishing or polishing of small parts? Centrifugal Finishing works especially well on small parts and parts with intricate details or complex geometry. With the increased pressure generated by the centrifugal force much smaller media can be utilized effectively to access features on small and complex parts. See some examples of small part finishing here at this link: https://dryfinish.wixsite.com/iso-finish/single-post/centrifugal-iso-finishing-hands-free-high-speed-deburring-finishing-polishing-of-small-parts

Can large parts be processed? New equipment designs make it possible to run much larger parts than previously was the case. The largest standard machine, the HZ-330 feature four different compartments with 12 inch (approx. 300mm) diameter compartments that have a barrel compartment length of 42 inches (approx. 1066mm). Recently, a custom-built machine, a Model HZ-600 had 62 inch long barrels. See the tech blog page here:

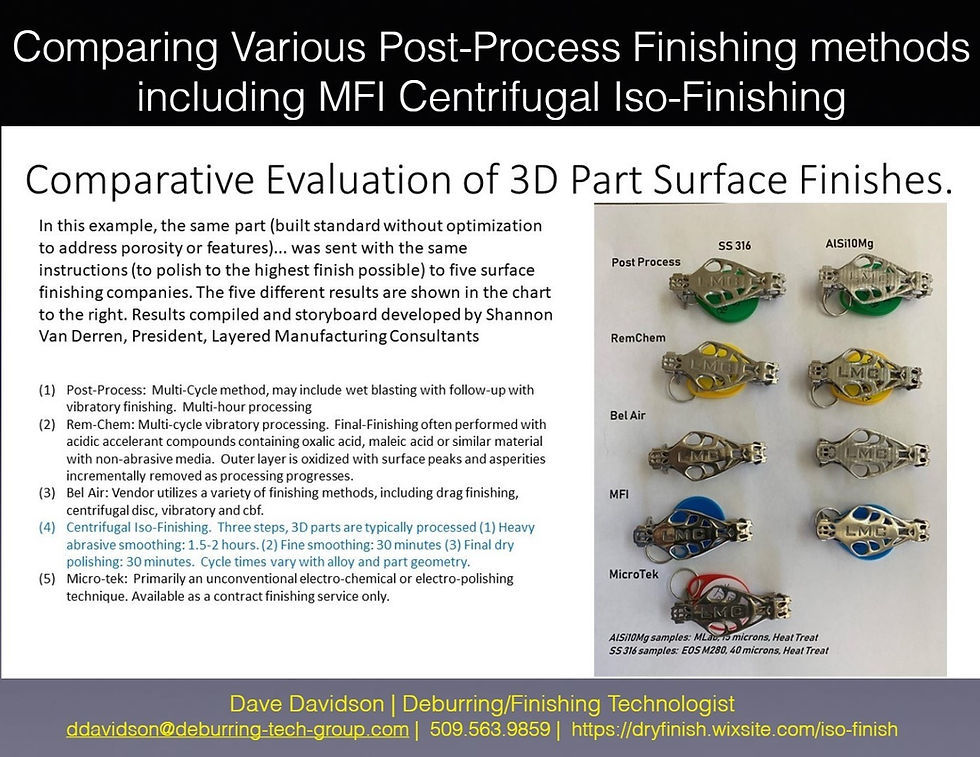

Can 3D printed parts be surface finished with Centrifugal Iso-Finishing?

Yes, many 3D parts are now being finished with Centrifugal Iso-Finishing processes.

Some examples of the processes that can be performed can be seen on these web-pages:

https://dryfinish.wixsite.com/iso-finish/single-post/2019/07/15/high-speed-and-hands-free-post-process-surface-finishing-of-3d-printed-or-additive-manufa Not just metal parts but plastic and parts from nylon/composition materials can be effectively surface finished with the method.

ABOVE: An example of some 3D printed parts showing before and after Centrifugal Iso-Finish processing.

I currently use vibratory finishing for the deburring and finishing of my machined parts, is there an advantage to centrifugal finishing on these types of parts.?

Several. Centrifugal iso-finishing typically processes parts 5 to 10 times faster than conventional vibratory finishing processes. Also, as the process is a high-pressure media process using centrifugal force to push media against the parts, much smaller media can be used for the deburring and finishing process. With conventional finishing processes, the media is often too large to access important areas and features of the part which means that they now may require a measure of hand-deburring or finishing. When finished in a centrifugal process this handwork is minimized and, in many cases, eliminated. Many shops with burdensome amounts of hand-deburring have seen significant savings from transitioning over to centrifugal iso-finishing. Here is a case study of one large contract machining operation that did just that: SEE: https://www.youtube.com/watch?v=dUdKjaysTYM

Is there a way that I can try before I buy? Check out our FREE sample part processing program.

If you have any questions or if there is any way that I can be helpful please contact me at ddavidson@deburring-tech-group.com or call me on my iPhone at 509-563-9859. International callers can reach me by using the WhatsApp phone application.

Comments